Potentials of Artificial Intelligence in the Construction Industry

The State of the Art report requires the investigation of an in-depth study and the preparation of professional quality report of approximately 10,000 words on a particular construction-related subject area. The level of study must be broad enough to constitute an "in depth" study and to present a challenge, but not so broad as to defy analysis and synthesis in the time available. The chosen paper goes in depth in exploring the potentials of artificial intelligence in the construction industry and the challenges that come along with it.

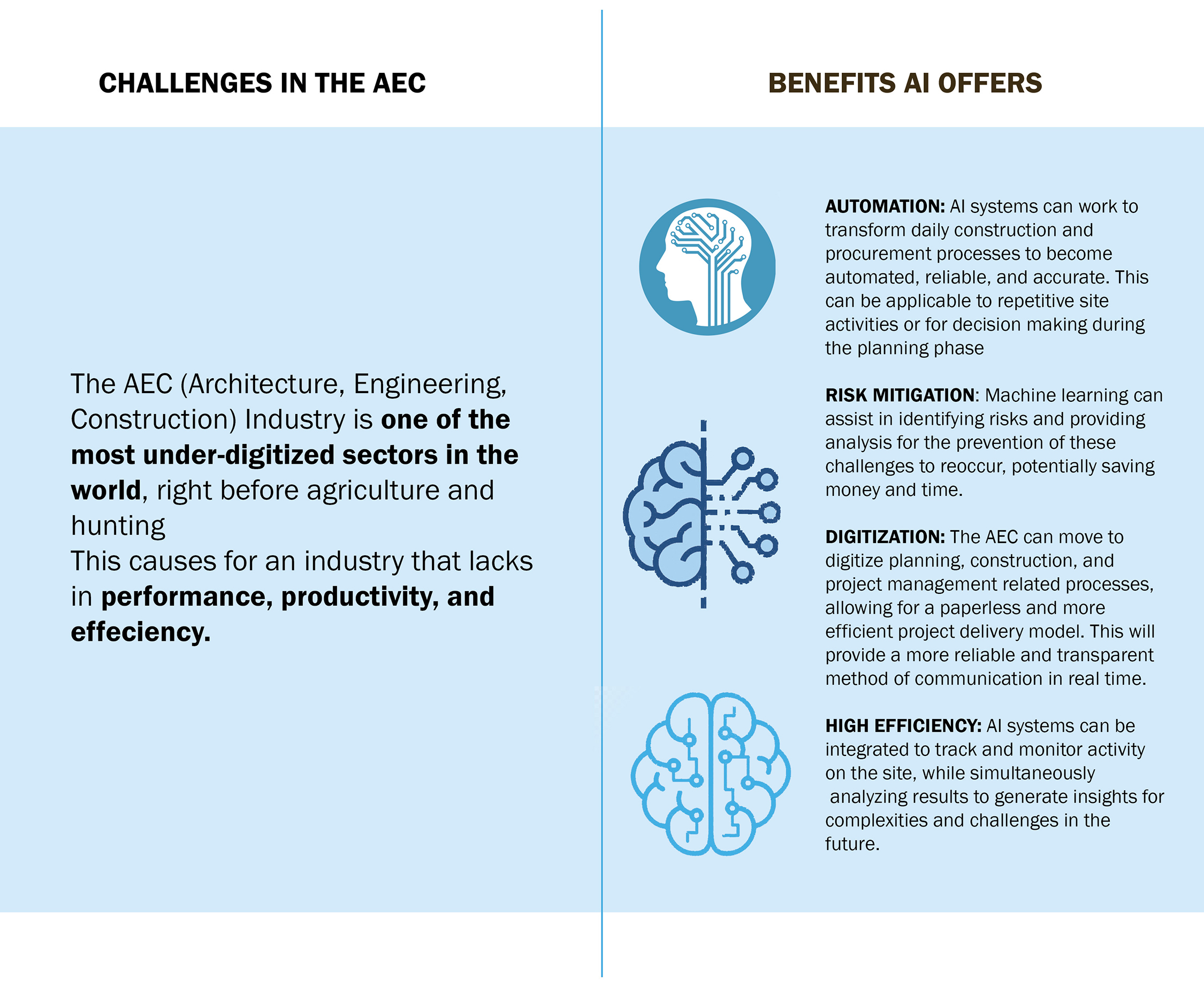

The architecture, engineering, and construction sector (AEC) plays a prominent role in the world’s economic growth and continually contribute long-term development initiatives. With its significant contribution to the worlds GDP and infrastructure expansion, it is important for the sector to evolve and integrate systems to ensure and optimize long term improvements for productivity, operation, and reliability. Artificial Intelligence (AI) has been adopted into multiple industries to provide automated, self learning smart machines to optimize performance, however the construction sector falls significantly behind by being one of the most under-digitized industries in the world which fails to adopt technological advancements in total. (Rao, 2019). Although AI and smart systems are slowly being introduced into the AEC to increase on-site productivity, efficiency, and provide various solutions for a project lifecycle, it is still in its early phase of adoption. This paper will highlight the potential and current uses of AI in AEC, benefits it provide, and any challenges that may arise in the project lifecycle.

View full report HERE.

View full report HERE.

Benefits and Uses of AI in AEC:

Adopting AI methods and systems in CEM will be beneficial for improving overall life cycle performance and profitability. AI can stand out as a “transformable technology to potentially bring about unprecedented changes” in the industry and relieve tasks that are labor intensive, complex, unique, and dynamic. (Pan et.al, 2021). It will aid in all aspects of a construction project; from conception to hand-off, proving to be valuable for all members involved. With the expected increase in interest and investment for AI in CEM, these intelligent systems will be able to provide suitable models to deliver promising solutions through “prediction, optimization, and decision making” to assist in construction project delivery. (Pan et.al, 2021).

The various benefits that the adoption of AI can offer in comparison to traditional methods are discussed below.

Automation:

AI systems can work to transform the daily tasks that come along with construction and procurement processes to become automated, reliable, and accurate. Pan et.al (2021) speak of the benefits machine learning algorithms could provide in automating construction tasks and project management duties through intelligently processing accumulated data for “hidden knowledge discovery”. This could be used to “facilitate automatic data analysis and decision making”, in turn increasing productivity rates and eliminating as much wasted time as possible.

Automation can also be applicable to on site activities which are tediously completed through the use of manpower and labourers. This could mean allowing repetitive tasks, such as brick laying or rebar tying, to be automated and not through human work. Drones, cameras and sensors can be integrated with AI technology to automatically record data, images, and videos to monitor construction status, environment, and progress. This would be useful to project managers and site supervisors on keeping track on any changes that may need to be made in real time. This would also provide an opportunity for “automatic methods to replace manual observation methods which can be time-consuming, tedious, and error-prone.” (Pan et. al, 2021).

Risk Mitigation:

AI systems and machine learning can assist in identifying risks and providing analysis to prevent these challenges to reoccur, reducing the tedious work of manual risk mitigation. The potentials AI bring forward for risk analysis are summarized as “AI can monitor, recognize, evaluate, and predict potential risk in terms of safety, quality, efficiency, and cost across teams and work areas even under high uncertainty, which has been predominantly adopted for risk identification, assessment, and prioritization.” (Pan et. al, 2021) Through a system which can identify and predict risks in real time, there is a great increase in not only productivity but also accuracy and reliability.

An AI integrated risk analysis system would also address the challenges and limitations of traditional risk analysis methods, which can be vague and vulnerable to errors. The McKinsey journal (Blanco et, al, 2018) discusses the importance of such systems in the construction industry, as it can utilize “predictive applications to foresee project risks, constructability, and structural stability” of various designs or solutions, and save millions of dollars down the roads and multiple hours in total.

High Efficiency:

AI systems can provide the ability for time bearing activities to be analyzed and deployed at a much higher rate of efficiency with less errors as opposed to traditional methods. AI enabled approaches using process mining (discussed in 3.4), which generates insights for complicated construction procedures, would aid in tracking workflow, predicting deviations from original schedule, collaborative efforts and patterns, and more. (Pan et. al, 2021) With a system that can derive all these conclusions at the speed of light through data collection and very deep learning methods, the results that are produced are of high quality with very little room for errors.

This can overall improve the efficiency of work both on-site and behind the scene for project managers, engineers, architects, etc. Since AI systems are also self-learning, there is a reduction in time for training, allowing for this saved time to be used for ensuring the absolute success of project delivery.

Digitization:

Adopting AI models into construction will mean that the construction industry will move to digitizing more processes, allowing for a paperless and more efficient project delivery model. This can allow for the overall adoption of technical systems, from on site to in the office, to provide a more accessible and reliable method of project delivery.

There are various systems which currently working to make this concept a reality in the sector, with BIM as the digital backbone for the integration of AI. BIM has proven to be one of the most useful software for digital collaboration and information processing, as it is able to collect large amounts of data about all aspects of the project and make the information readily available to all team members. Traditional construction practices are not easily accessible and have proven to be inefficient for communication and collaboration. Systems such as BIM allow for sharing, exchanging, and analyzing in real time for communication and collaboration (Pan et. al, year) in a transparent and accessible manner. Data from BIM can also be used to automate and improve construction processes overall, while remaining paperless and using smart technology to track risk and process.

China’s Baihetan Dam:

China’s newest hydropower plant, Figure 5, was completed in July 2020 through AI integrated systems to significantly increase the delivery process of the dam. A dam that would have typically taken 10 years was able to be completed in just 4 years through the integration of smart systems on site to monitor and improve site productivity. (Chen, 2021).

The dam stands “nearly 985 meters tall and is made with more than 8 million cubic meters of concrete” becoming the world’s second largest dam capable of “dwarfing the production of America’s Hoover Dam”. (Chen, 2021). Due to the already ambitious deadline in combination with the Covid-19 outbreak, there were concerns on if the project would be delivered in time.

This initiated the integration of AI technology which was implemented for the entirety of the project and governed almost everyone that was part of the team, “from site workers to engineers, quality inspectors and senior managers” (Chen, 2021). The main form of AI that was used for this project was the positioning of a 4G network and satellite system to track and instruct the path of travel for trucks brought onto site. “The system constantly adjusted traffic by monitoring cement mixing plants, cable machines, real tie demand on the pouring site, and remapping routes instantly if required.” (Chen, 2021). This reduced the chance of a long waiting line for trucks to enter the site, preventing the chance of slowing the project down.

Due to the integration of AI, accidents were also rare on the site since the smart system would “issue an early warning and push the information to site management personnel to eliminate a mistake before it became a problem.” (Chen, 2021). The system also worked to control the mixing, pouring, and cooling of the cement process, resulting in no errors upon inspection through the quality inspector.

Through the monitoring and surveillance of AI integrated systems, the dam was able to reduce the scheduled delivery date by 6 full years and deliver a more reliable infrastructure in the end.