Year 2

Emma Chudoba—Craig Race Passive Sustainability Design Award

About the Award

For an undergraduate student who demonstrates creativity in the use of passive design strategies in a studio project to improve its sustainability.

![]()

![Parti]()

![Exterior]()

![Interior]()

Emma Chudoba—Craig Race Passive Sustainability Design Award

About the Award

For an undergraduate student who demonstrates creativity in the use of passive design strategies in a studio project to improve its sustainability.

YEAR 2

Tyler Chui—Matthew and Anne Tomljenovic Award

![]()

Tyler Chui—Matthew and Anne Tomljenovic Award

About the Award

Highest CGPA average among the second-year Architecture courses.

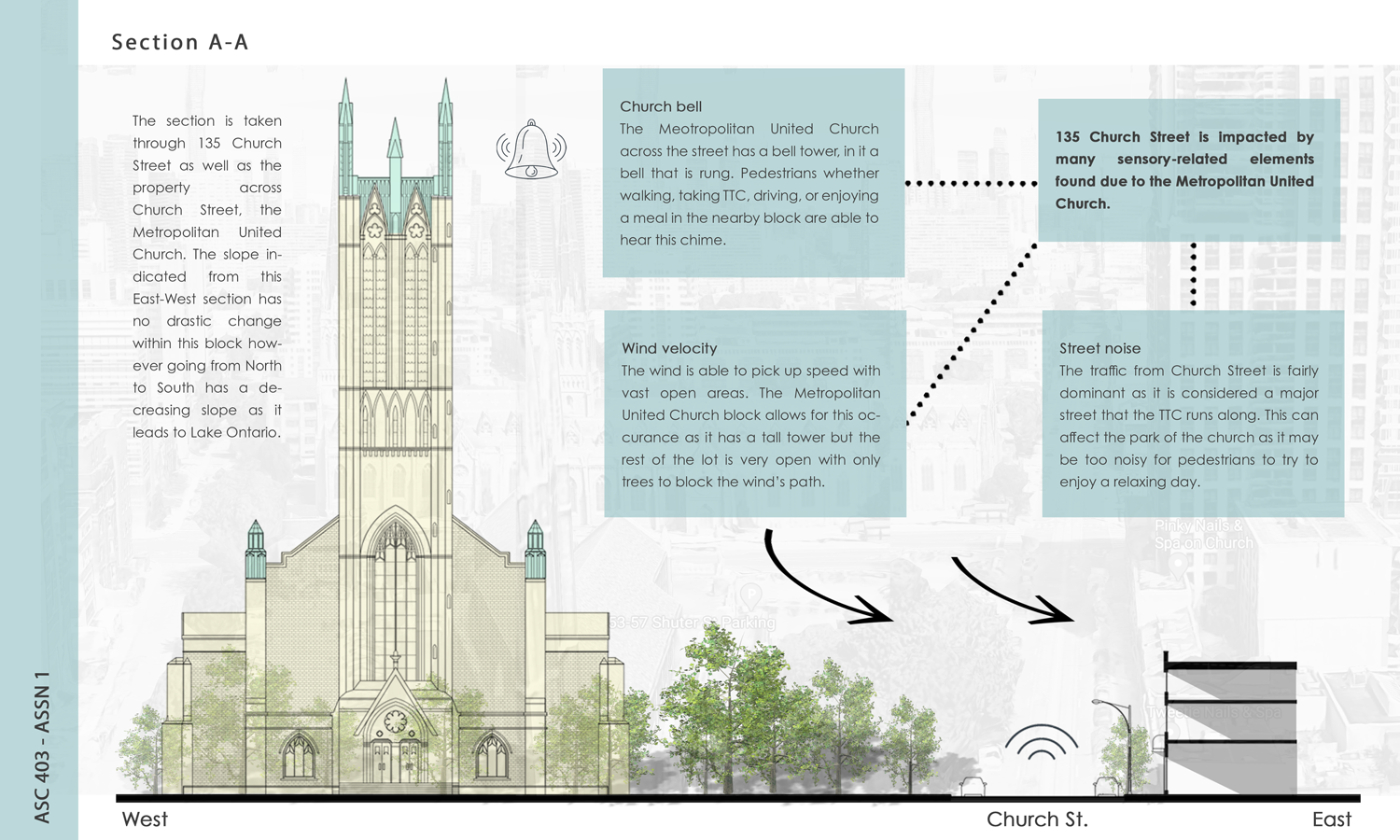

ASC403

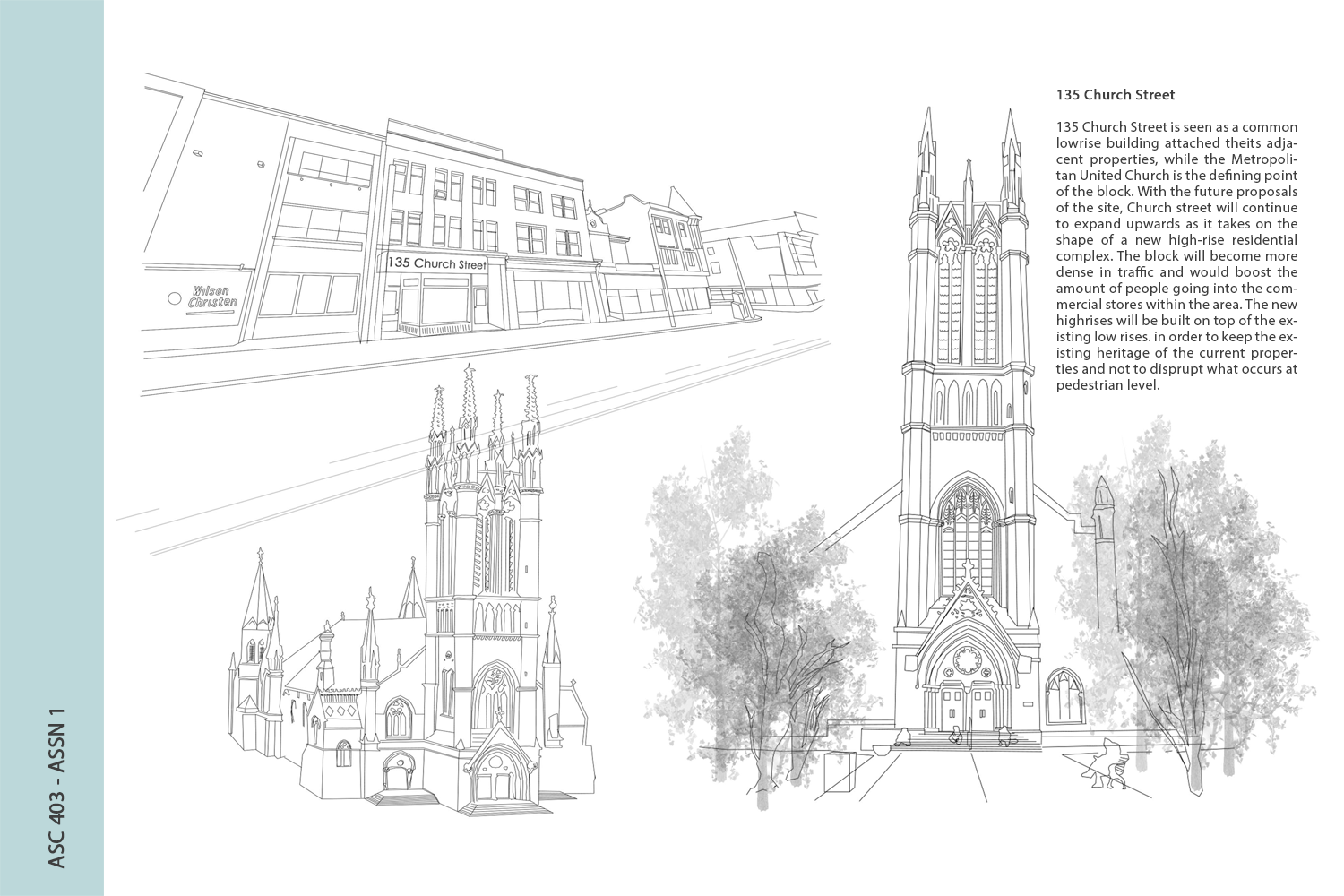

For assignment 1, students were given a site located in Toronto and individually had to research the history, uses, circulation, access, and legal framework. With this research, to then analyze the site and conclude theories on how it is shaped by the urban context and whether its an area of interest to be revitalized. The site allocated for me was 135 Church Street across the street from the Metropolitan United Church.

Assignment 2 was a group project where we had to design a proposal to redesign an area of interest from our previous individual project. My group members were Eric Bowen, Hajara Nida Hameed, Hyun Jung (Joshua) Kim and myself, where we analyzed the Metropolitan United Church and its surrounding buildings. Our goal was to promote biodiversity throughout the site by creating a natural environment that would attract local species of bees and birds and improve the existing vegetation within the site. We also aimed to increase the circulation and reduce the amount of surface runoff by using the filtered water to feed the surrounding vegetation and circulate the collected water back into Lake Ontario.

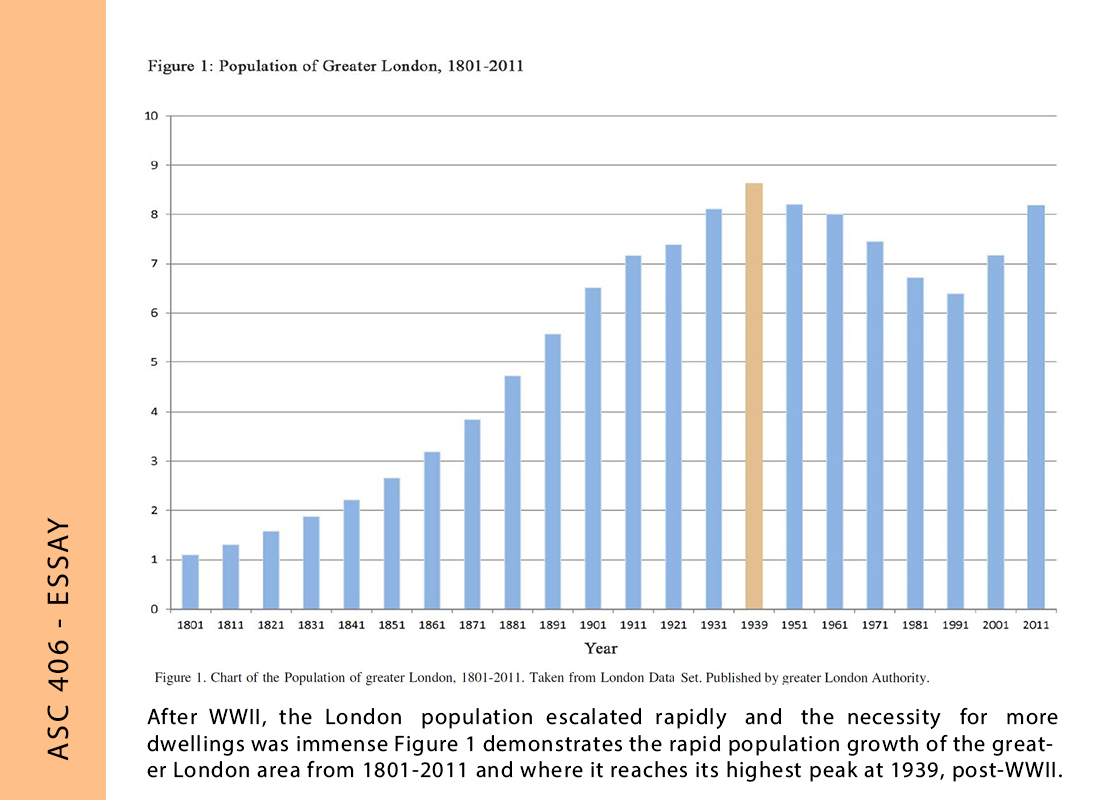

ASC406

For our final essay, we were required to research a given topic, time period and location and discuss its impact on the society of that time. My topic was London dwellings during the post-war period where I examined the housing necessity due to the population growth and the LCC’s partake in this matter. I further discussed the inflation of construction overseen by the LCC to conclude the increase in population post-war negatively affected the well-being and living environments of the city of London.

YEAR 2

Jillian Sproul—Matthew and Anne Tomljenovic Award

About the Award

Highest CGPA average among the second-year Building Science courses.

![]()

![]()

![]()

Jillian Sproul—Matthew and Anne Tomljenovic Award

About the Award

Highest CGPA average among the second-year Building Science courses.

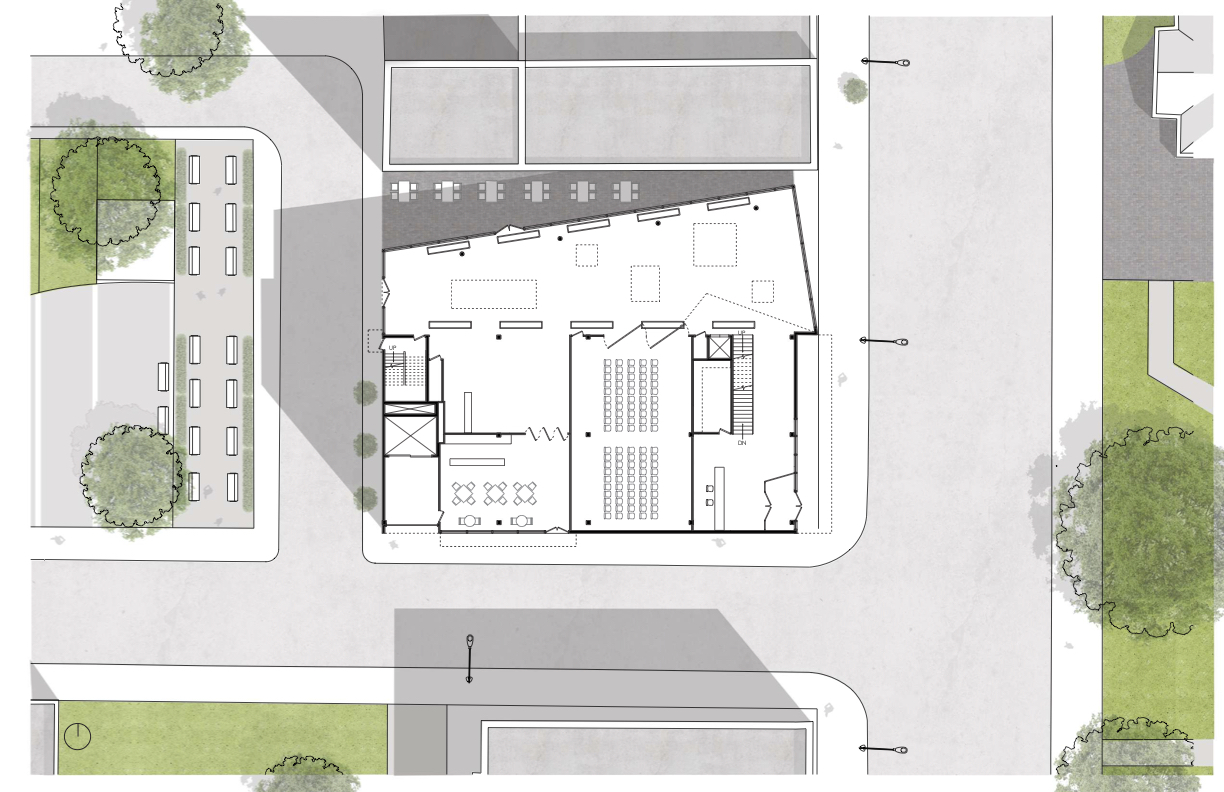

In the heart of Toronto’s downtown core, 650 Church St. provides a large corner site with promising circulation surrounding. ‘Pivot’ proposes a museum dedicated to the exhibition of the Canadian bike company Cervélo. Bikes will be displayed throughout the museum for the public to enjoy and educate themselves on the sport of bike racing. With inspiration taken from the distinct geometries of the Cervélo bike’s body, ‘Pivot’ plays on the idea of pivotal points branching off of a permanent form. ‘Pivot’ works with this idea by maintaining a central atrium, with a distinct geometry, that allows for pivotal points to branch off controlling the visitors’ circulation. These intense turns and new spaces, wrapping the perimeter of the atrium and feature bike wall, allow for different moments to be hidden then found.

YEAR 2

Jillian Sproul—Ted Libfeld BILD Scholarship

About the Award

For the third-best overall performance in the area of Management and Construction/Theory in the second-year.

Project Description:

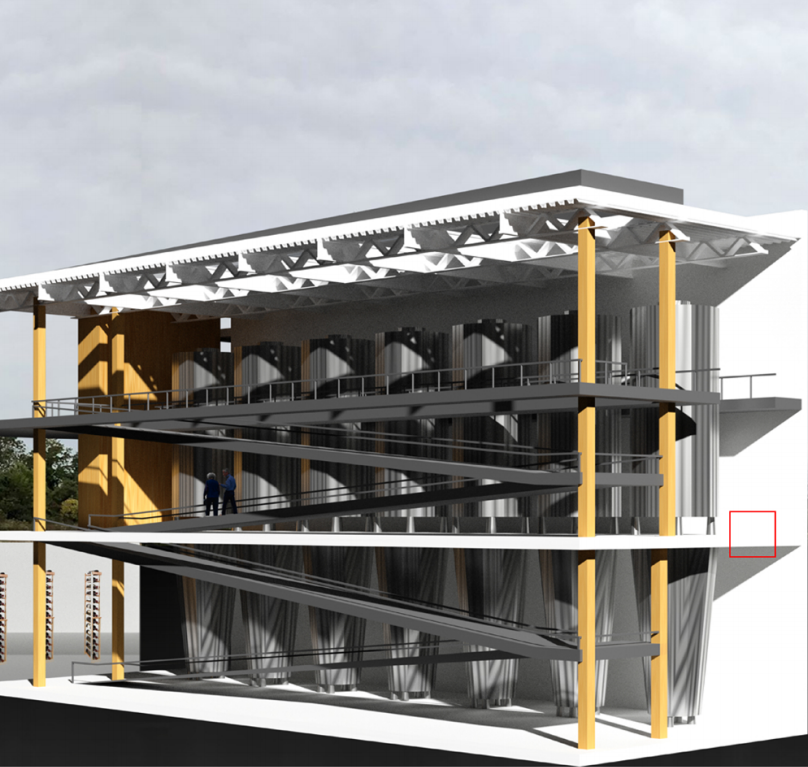

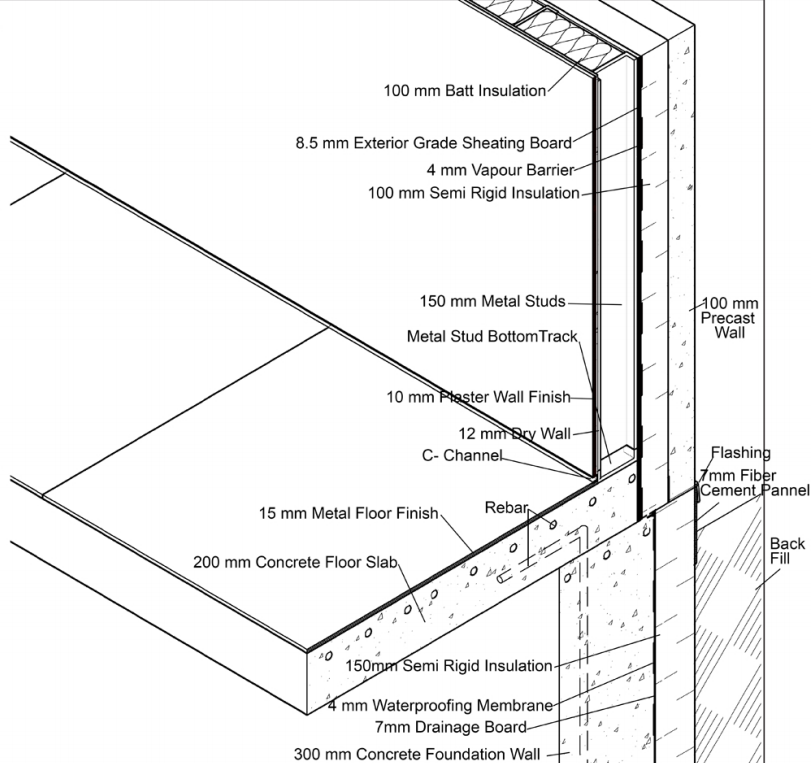

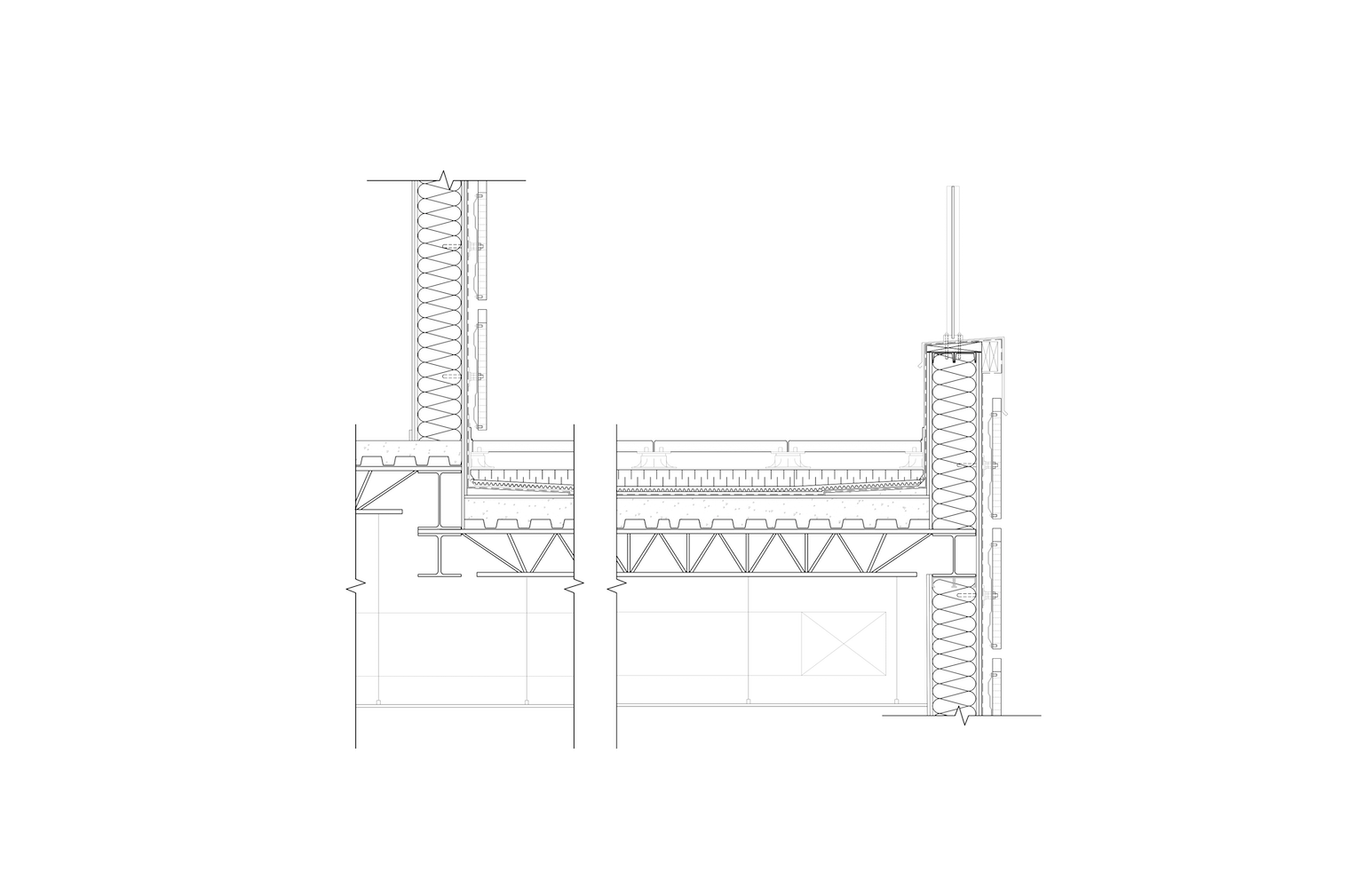

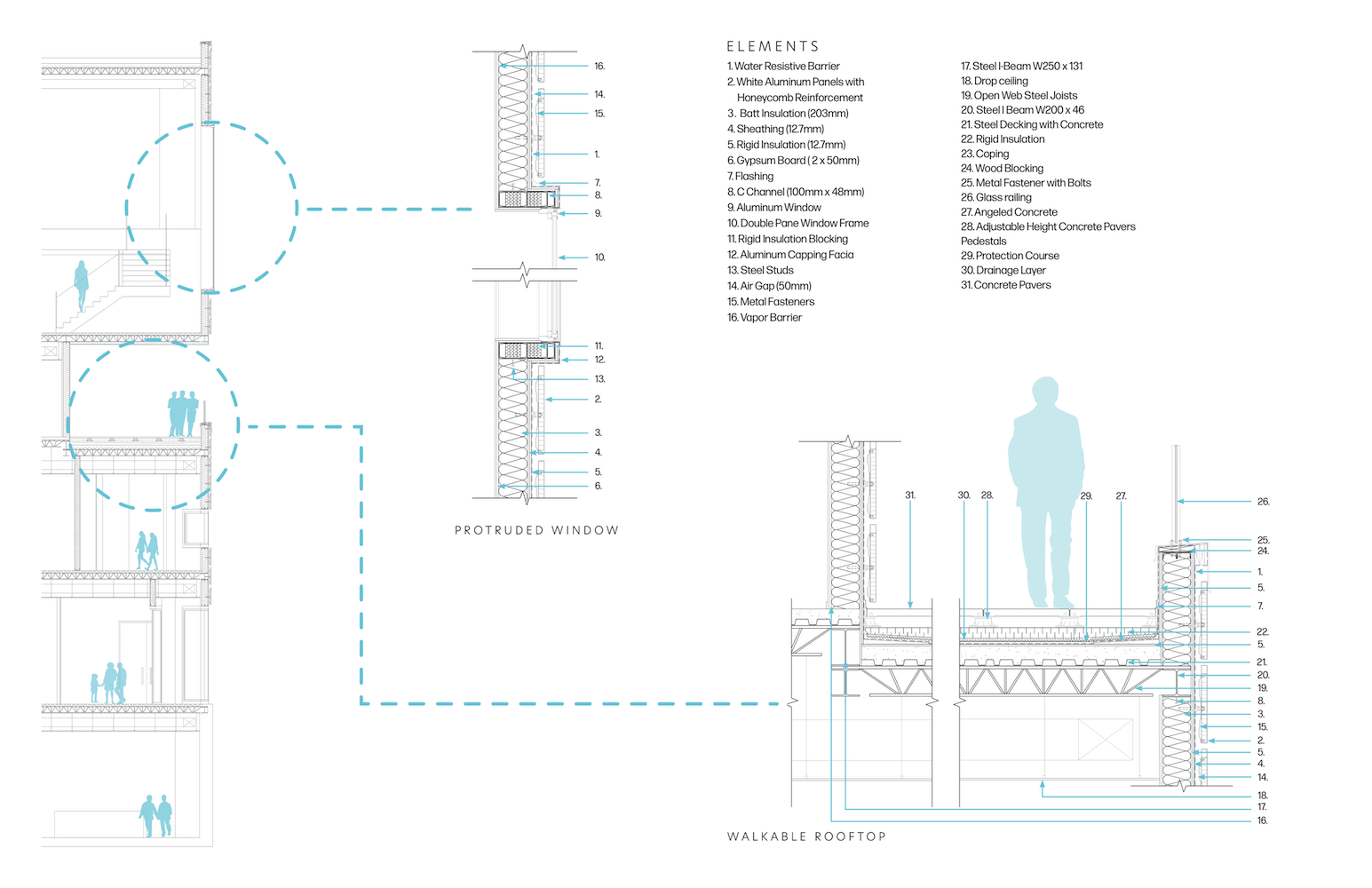

The winery ‘Aperture’ suggests a gravitational wine making process while taking inspiration from the landscape to provide an architectural expression. ‘Aperture’ focuses on the concept of solid and void allowing for visual transparencies through the building and visual connections to the surrounding landscape. As the intent of creating a building that reads as a void within a solid, a large mass within the flat landscape was created. Due to this architectural expression, a sturdy structure able of creating large spans was necessary. The chosen structure of CLT allows for structural stability and ease of construction for the large mass that the building conveys. The intent of solid and void is most clearly seen in the glass curtain wall framing the void within the landscape, however, the beginning of prominent voids can be seen in the roof line. As the chosen detail focuses in on the beginning of a new roof line, elements of cladding and structure are seen interacting. The simplistic structure of CLT allows for clean volumes to be created on the inside while on the outside locally sourced materials are used to enforce the concept. The larch wood siding creates a three-dimensional façade that exaggerates the ideas of the void protruding through the surface. This is expressed as the facade is extruded from the large glazing allowing the idea of void to be noticed during the approach. As Niagara-on-the-Lake, has a climate of high levels of precipitation cladding such as larch wood that has been pre-treated is ideal to resists weathering thus, the chosen materials work with both the architectural expression and the structural needs of the building. Overall, ‘Aperture’ illustrates the methods of construction for large buildings that can utilize faster construction methods all while taking into account the impact of sustainable design on the surrounding environment.

Jillian Sproul—Ted Libfeld BILD Scholarship

About the Award

For the third-best overall performance in the area of Management and Construction/Theory in the second-year.

Project Description:

The winery ‘Aperture’ suggests a gravitational wine making process while taking inspiration from the landscape to provide an architectural expression. ‘Aperture’ focuses on the concept of solid and void allowing for visual transparencies through the building and visual connections to the surrounding landscape. As the intent of creating a building that reads as a void within a solid, a large mass within the flat landscape was created. Due to this architectural expression, a sturdy structure able of creating large spans was necessary. The chosen structure of CLT allows for structural stability and ease of construction for the large mass that the building conveys. The intent of solid and void is most clearly seen in the glass curtain wall framing the void within the landscape, however, the beginning of prominent voids can be seen in the roof line. As the chosen detail focuses in on the beginning of a new roof line, elements of cladding and structure are seen interacting. The simplistic structure of CLT allows for clean volumes to be created on the inside while on the outside locally sourced materials are used to enforce the concept. The larch wood siding creates a three-dimensional façade that exaggerates the ideas of the void protruding through the surface. This is expressed as the facade is extruded from the large glazing allowing the idea of void to be noticed during the approach. As Niagara-on-the-Lake, has a climate of high levels of precipitation cladding such as larch wood that has been pre-treated is ideal to resists weathering thus, the chosen materials work with both the architectural expression and the structural needs of the building. Overall, ‘Aperture’ illustrates the methods of construction for large buildings that can utilize faster construction methods all while taking into account the impact of sustainable design on the surrounding environment.

Step

1: Structure

The first step of construction would involve the flattening of the land and the pouring, curing and setting of the concrete foundations. From there 300 mm x 300 mm CLT columns would be fastened to the foundations through steel sill plates and anchor rods creating rigid connections to the ground. From the CLT columns a one-way system of 300mm x 300mm CLT beams will be attached through partially threaded timber screws. Additional supports of Ricon/ Megant style connectors will be added to the column to securely attach the beam. The 80 mm CLT roof panels and 100 mm wall CLT panels will then be attached to the beams through partially threaded timber screws which will reach fully through the panels to the beams. During this process, the angled roof will require attachments at the connection surface area using fully threaded timbers screws inserted in a ‘X’ like fashion crossing through both surfaces. This will secure the panels together as all screws are roughly the length of the panel thickness.

Members outlined:

Step 2: Sub Structure and Control Layers

After the first step of initial CLT structure is installed, the substructure can then be followed. However, before the substructure can be installed, the vapour barrier must be placed before due to the manner in which CLT construction occurs. The 0.05 mm polyethylene sheet is placed on the warm side of the insulation in order to restrict water vapour movement. The substructure of 2 x 6 (38 mm x 140 mm) can then be placed and is constructed to allow for the cladding in the future steps to have an attachment surface. The substructure is installed as a light frame construction using joists to encase the insulation batts and allow for attachment surfaces.

Members Outlined:

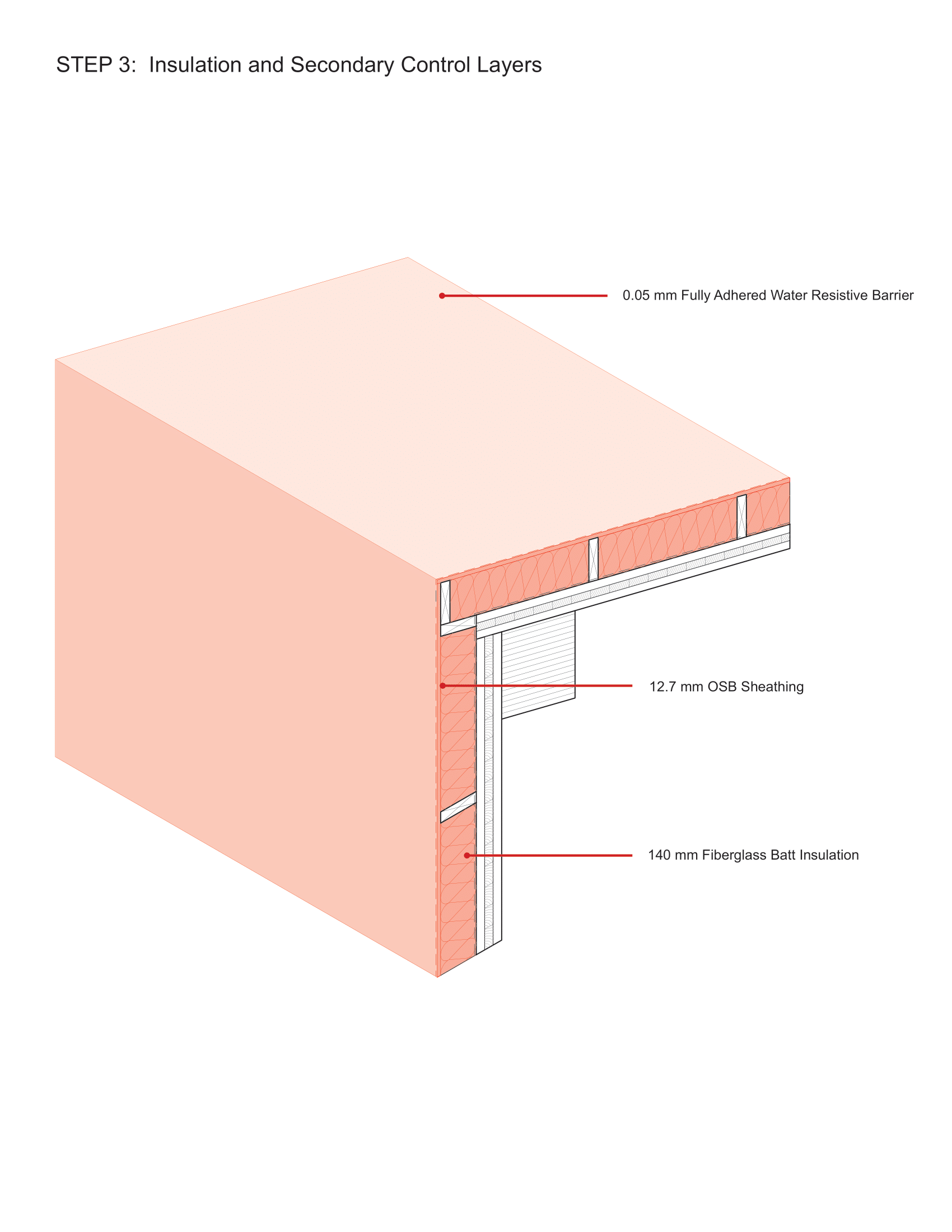

Step 3: Insulation and Secondary Control Layers

Following the installation of the substructure the fiberglass batt insulation is placed between the running joists. To encase the insulation, 12.7 mm oriented strand board is installed to the substructure. This is done with the use of hardware which will fasten the OSB to the joists below. The oriented strand board provides a hard flat surface for the water resistive barrier (WRB) to adhere to. The WRB is installed in pieces that overlap and are then sealed to allow for no water to penetrate the structure below. Now that a weather barrier is installed around the exterior surfaces the cladding can then begin to be installed.

Members outlined:

The first step of construction would involve the flattening of the land and the pouring, curing and setting of the concrete foundations. From there 300 mm x 300 mm CLT columns would be fastened to the foundations through steel sill plates and anchor rods creating rigid connections to the ground. From the CLT columns a one-way system of 300mm x 300mm CLT beams will be attached through partially threaded timber screws. Additional supports of Ricon/ Megant style connectors will be added to the column to securely attach the beam. The 80 mm CLT roof panels and 100 mm wall CLT panels will then be attached to the beams through partially threaded timber screws which will reach fully through the panels to the beams. During this process, the angled roof will require attachments at the connection surface area using fully threaded timbers screws inserted in a ‘X’ like fashion crossing through both surfaces. This will secure the panels together as all screws are roughly the length of the panel thickness.

Members outlined:

- 100 mm Cross Laminated Timber Wall Panel

- 300 mm x 300 mm Cross Laminated Timber Beam

- 100 mm Cross Laminated Timber Wall Panel

Step 2: Sub Structure and Control Layers

After the first step of initial CLT structure is installed, the substructure can then be followed. However, before the substructure can be installed, the vapour barrier must be placed before due to the manner in which CLT construction occurs. The 0.05 mm polyethylene sheet is placed on the warm side of the insulation in order to restrict water vapour movement. The substructure of 2 x 6 (38 mm x 140 mm) can then be placed and is constructed to allow for the cladding in the future steps to have an attachment surface. The substructure is installed as a light frame construction using joists to encase the insulation batts and allow for attachment surfaces.

Members Outlined:

- 38mm x 140mm Wood Substructure Joists to Attach Cladding

Elements

- 0.05 mm Polyethylene Vapour Barrier

- 38 mm x 140 mm Wood Substructure Joists to Attach Cladding Elements

Step 3: Insulation and Secondary Control Layers

Following the installation of the substructure the fiberglass batt insulation is placed between the running joists. To encase the insulation, 12.7 mm oriented strand board is installed to the substructure. This is done with the use of hardware which will fasten the OSB to the joists below. The oriented strand board provides a hard flat surface for the water resistive barrier (WRB) to adhere to. The WRB is installed in pieces that overlap and are then sealed to allow for no water to penetrate the structure below. Now that a weather barrier is installed around the exterior surfaces the cladding can then begin to be installed.

Members outlined:

- 0.05 mm Fully Adhered Water Resistive Barrier

- 12.7 mm OSB Sheathing

- 140 mm Fiberglass Batt Insulation

Step 4: Cladding

Attachment Structure - Strapping

Now that the WRB is installed and water can be repelled from the structure, the strapping for cladding application can be installed. Before the strapping, any flashing around windows and doors would be installed to make sure drainage flows away from the building. After the flashing, the vertical strapping, also known as battens (60 mm x 45 mm), would be installed to the OSB and fastened to the substructure beneath. From the vertical strapping, horizontal strapping, also known as counter-battens (50 mm x 30 mm) are fastened to the vertical members with the use of hardware. This will create an air gap allowing for water to penetrate the WRB and flow down to the flashing elements. Now that a secondary structure for cladding is installed, the larch wood siding can be placed.

Members Outlined:

Step 5: Cladding and Finishing Exterior Elements

The second final step of exterior cladding can now be finalized. The Siberian larch wood cladding will be pretreated for weathering before arriving to the site. Once arrived the pieces of wood will be attached to the horizontal strapping. This will be executed through the use of hardware that has also been weather treated to avoid damage from the winter climate. The cladding elements will conjoin at the edges of the roof and wall connection. At this connection a metal ridge cap will be installed to repel direct water from accessing the WRB. The ridge cap will also provide stability to the cladding elements and create a clean finish at the seams.

Members Outlined:

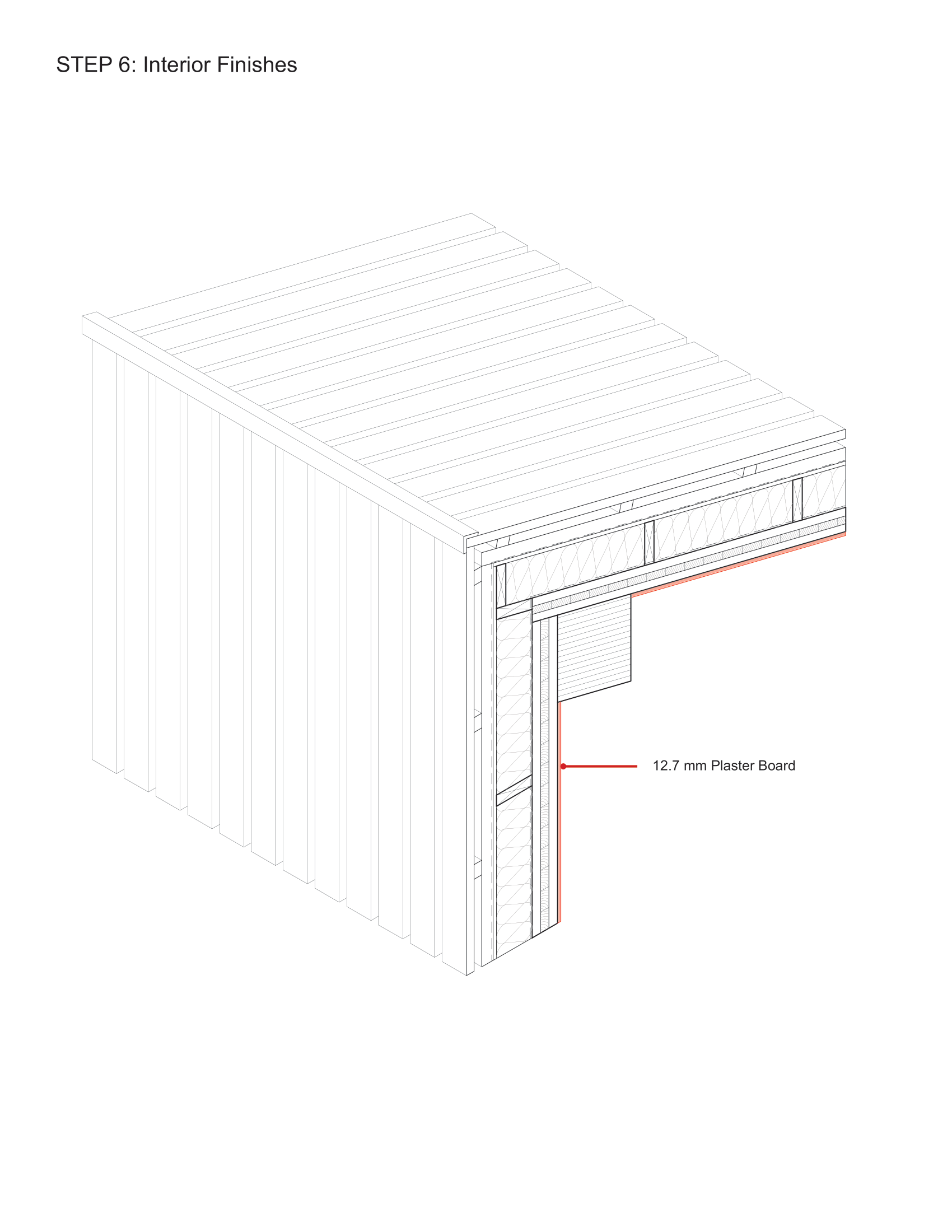

Step 6: Interior Finishes

Finally, once all the exterior layers have been attached, interior finishes can be applied. Plasterboard is fastened to the CLT panels creating a clean finish on the interior and sound control.

Members outlined:

Now that the WRB is installed and water can be repelled from the structure, the strapping for cladding application can be installed. Before the strapping, any flashing around windows and doors would be installed to make sure drainage flows away from the building. After the flashing, the vertical strapping, also known as battens (60 mm x 45 mm), would be installed to the OSB and fastened to the substructure beneath. From the vertical strapping, horizontal strapping, also known as counter-battens (50 mm x 30 mm) are fastened to the vertical members with the use of hardware. This will create an air gap allowing for water to penetrate the WRB and flow down to the flashing elements. Now that a secondary structure for cladding is installed, the larch wood siding can be placed.

Members Outlined:

- 50mm x 30mm Horizontal Wood Strapping (Counter- Battens)

- 45 mm Air Gap Between Strapping

- 60 mm x 45 mm Vertical Wood Strapping (Battens)

Step 5: Cladding and Finishing Exterior Elements

The second final step of exterior cladding can now be finalized. The Siberian larch wood cladding will be pretreated for weathering before arriving to the site. Once arrived the pieces of wood will be attached to the horizontal strapping. This will be executed through the use of hardware that has also been weather treated to avoid damage from the winter climate. The cladding elements will conjoin at the edges of the roof and wall connection. At this connection a metal ridge cap will be installed to repel direct water from accessing the WRB. The ridge cap will also provide stability to the cladding elements and create a clean finish at the seams.

Members Outlined:

- Metal Ridge Cap

- 30 mm x 95 mm Pre-Treated Siberian Larch Wood Cladding

Step 6: Interior Finishes

Finally, once all the exterior layers have been attached, interior finishes can be applied. Plasterboard is fastened to the CLT panels creating a clean finish on the interior and sound control.

Members outlined:

- 12.7 mm Plaster Board

YEAR 2

Hajara Hameed—Ted Libfeld BILD Scholarship

About the Award

For the second-best overall performance in the area of Management and Construction/Theory in the second-year.

Hajara Hameed—Ted Libfeld BILD Scholarship

About the Award

For the second-best overall performance in the area of Management and Construction/Theory in the second-year.